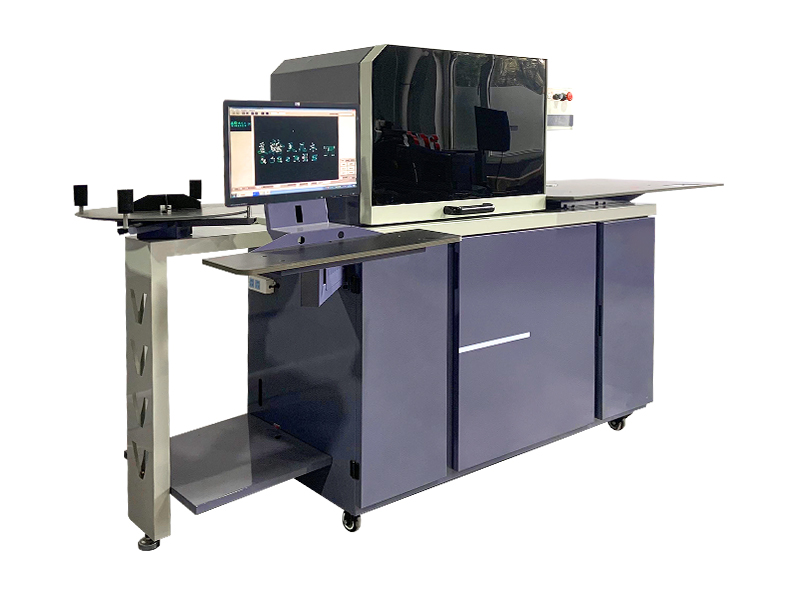

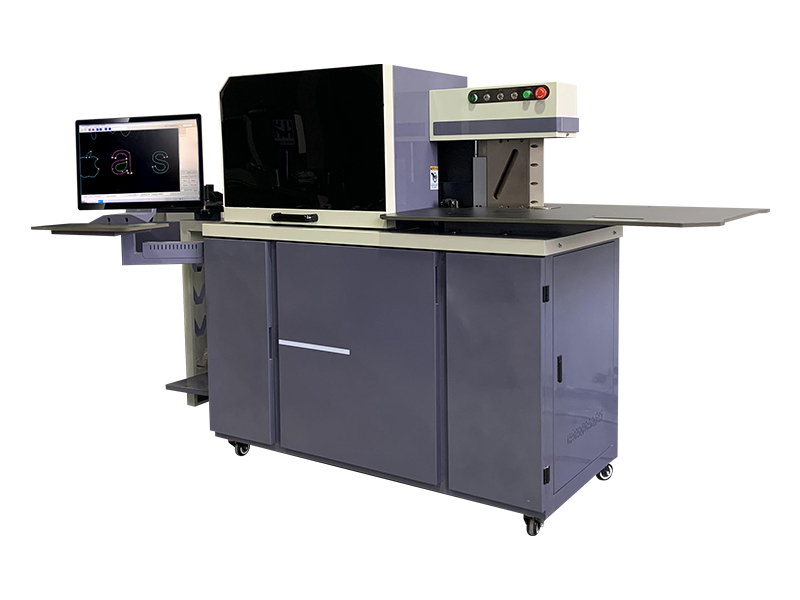

| Machine Size | 2.45×1.15×1.58m(M130)/2.7×1.2×1.6m(M220)/2.73×1.22×1.7m(M300) |

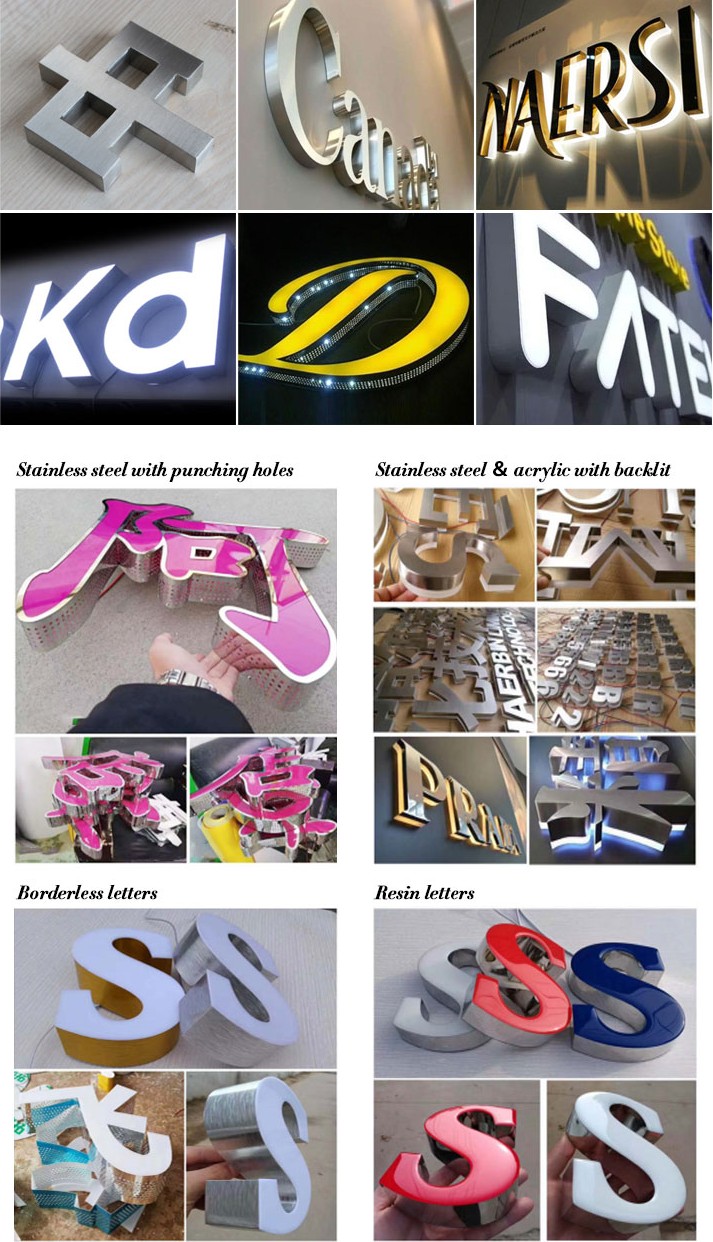

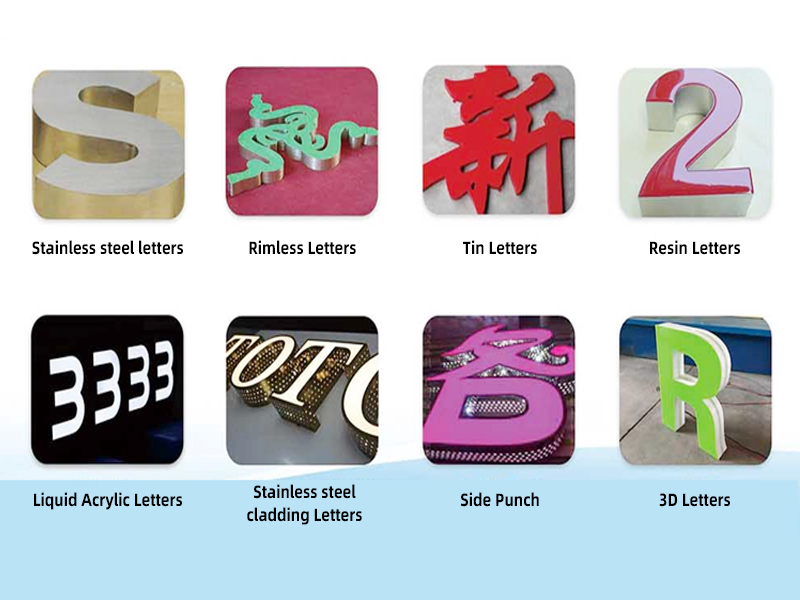

| Function | Automaticfeeding,slottingand bending |

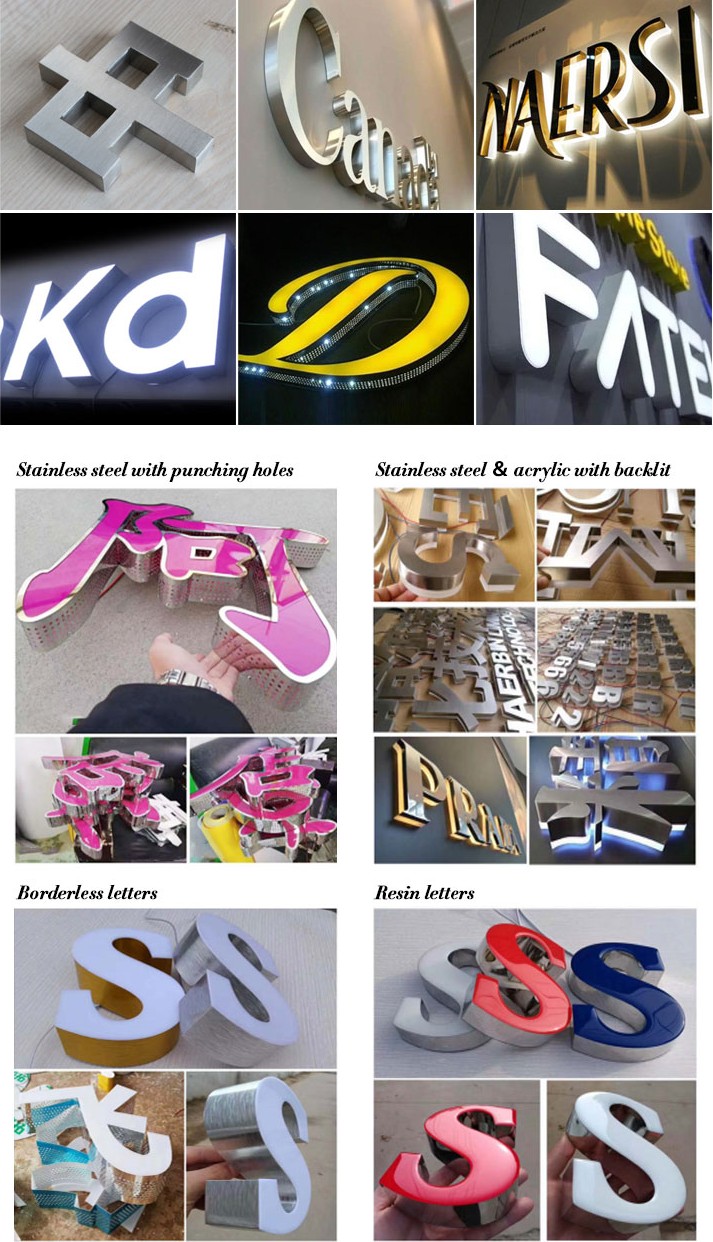

| WorkingMaterials | Stainless steel,Galvanized sheet,lron,FLAT aluminum coil |

| Material Width | ≤130mm(M130)/≤220mm(M220)/≤300mm(M300) |

| Material Thickness | 0.3~1.2mm |

| Bending Radius | ≥5mm |

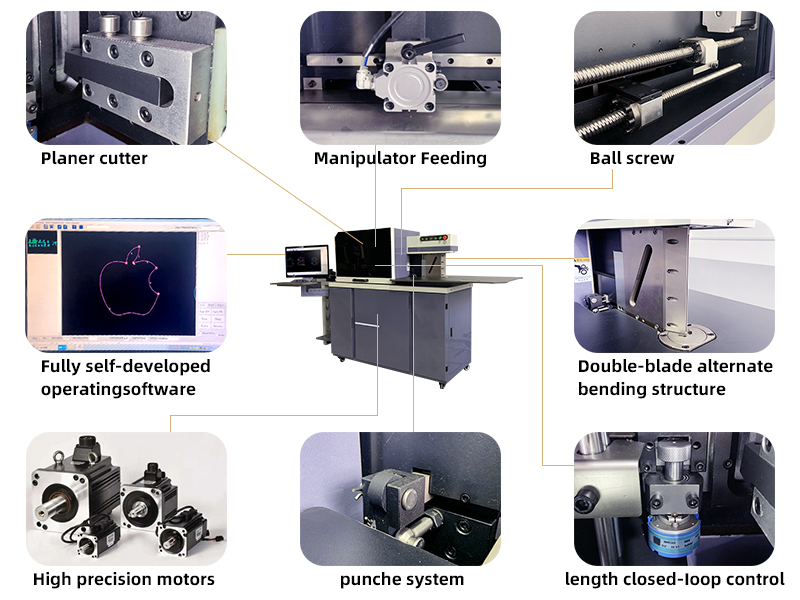

| Slotting System | Planing cutter |

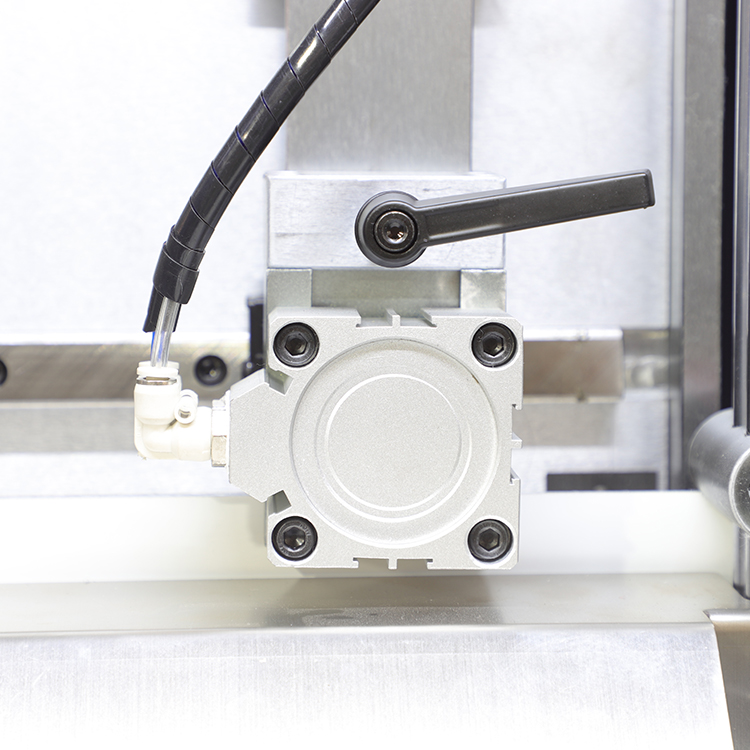

| Bending | Double-knifealternatingbending |

| Total Power | 2000W(M130/220)/2500W(M300) |

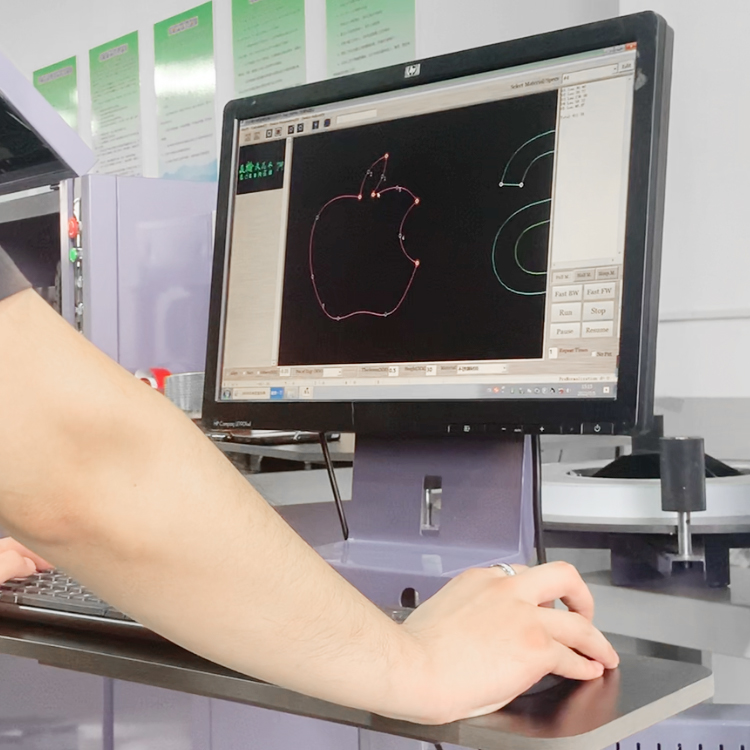

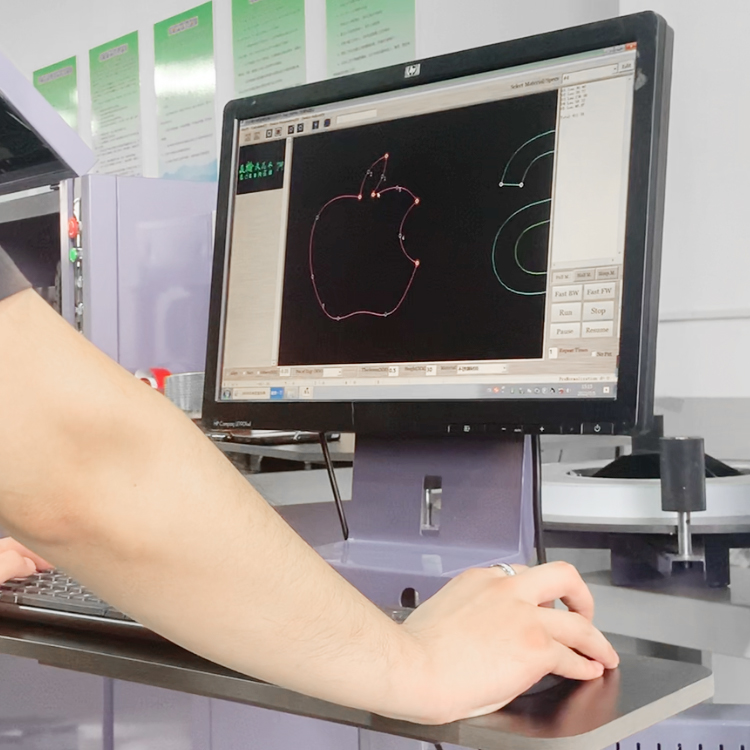

| File Format | Dxf,Ai,Plt |

| Working Voltage | AC220V,50~60Hz |

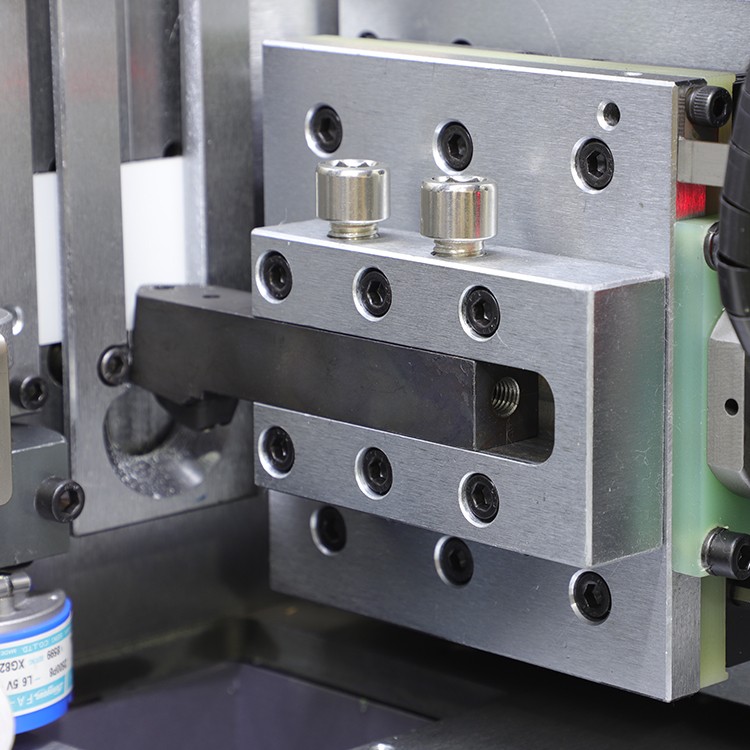

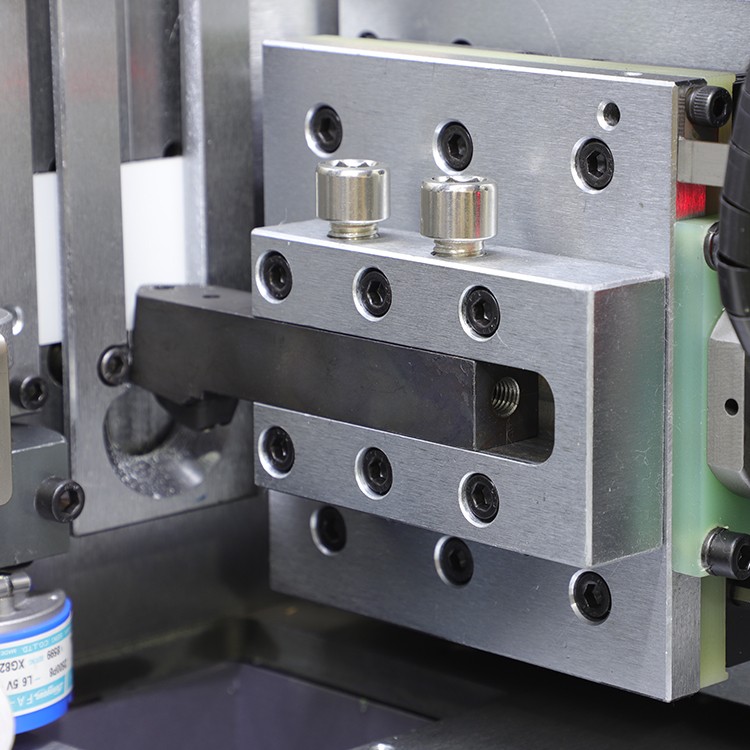

1.

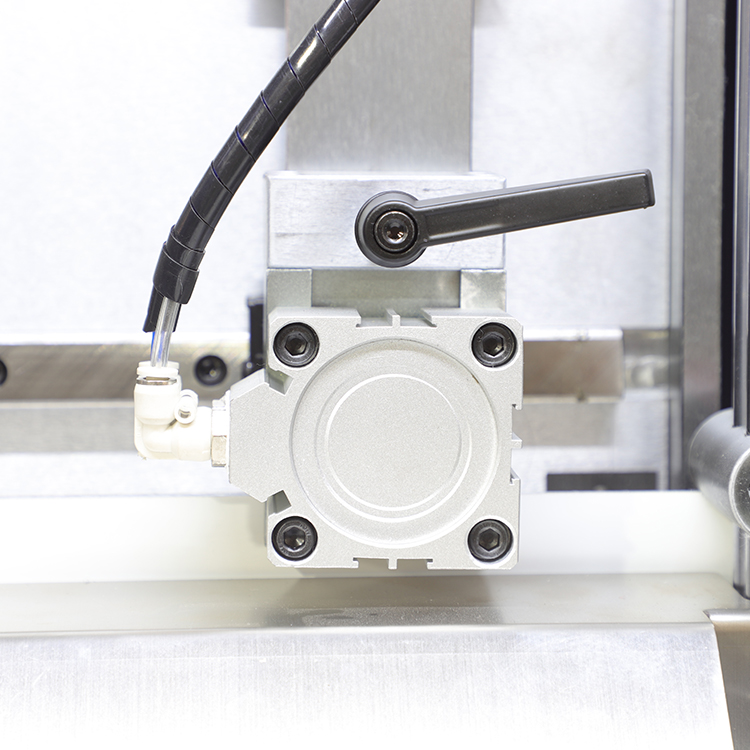

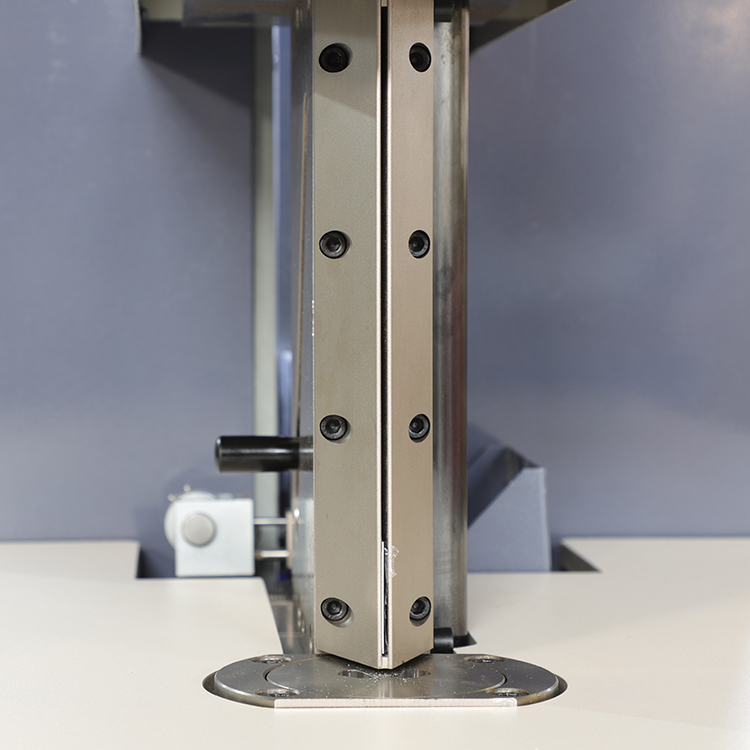

The robot alternate feeding mechanism is adopted to effectively ensure the stability of the

feeding process.

The material clip adopts structural castings,which can avoid scratching the material while improving the feeding grip.

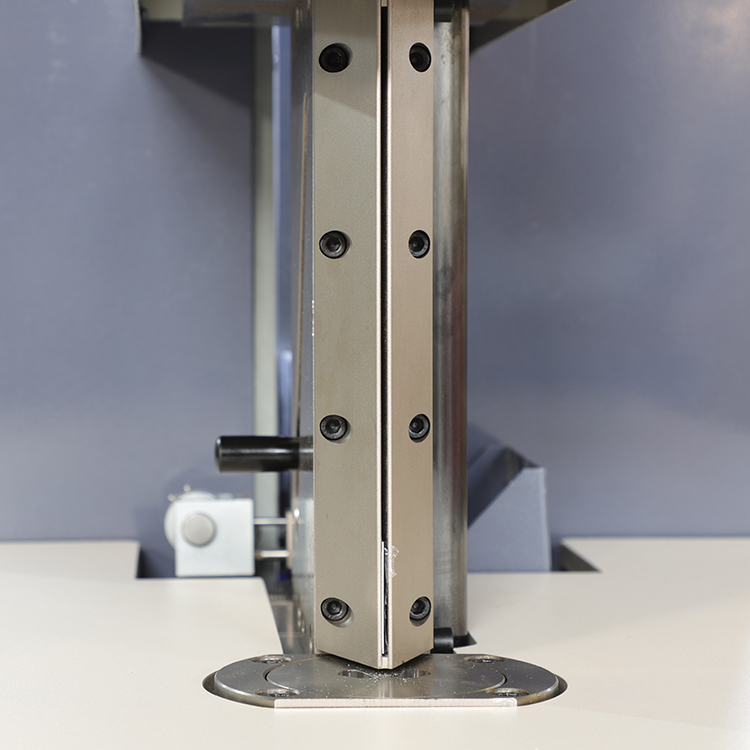

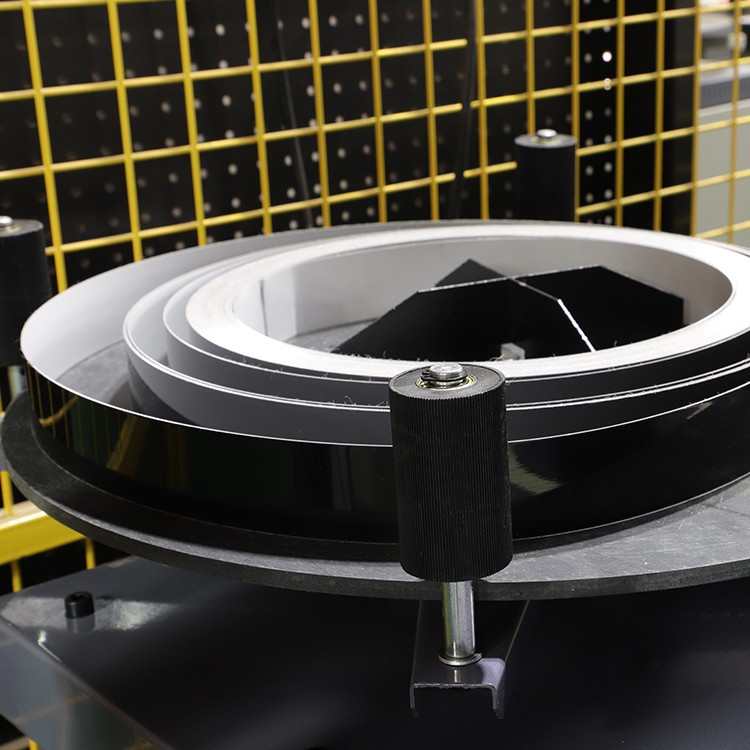

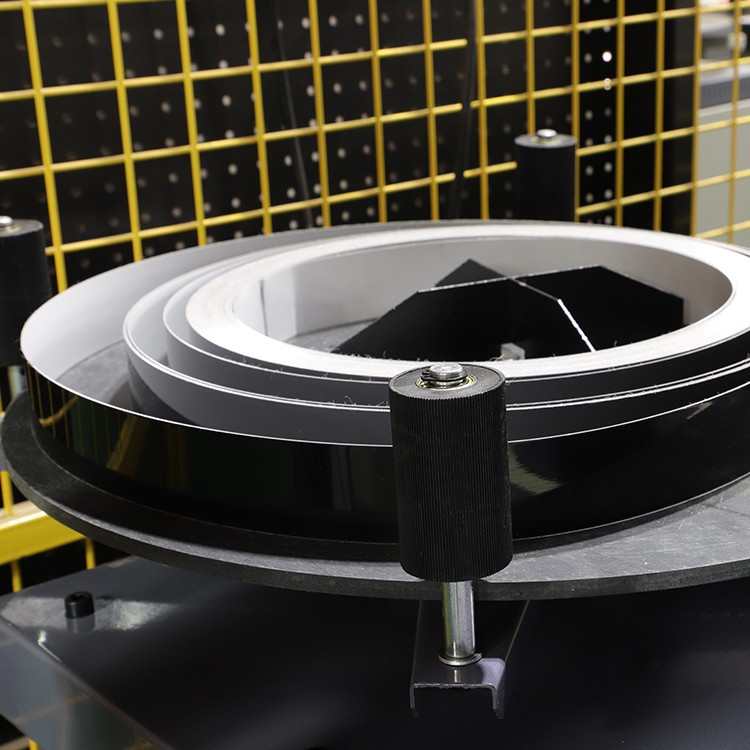

2.

Double-knife alternating bending structure,high forming degree and strong stability.

3.

The planer system realizes automatic adjustment of cutting depth and is easy to operate.

The planer is made of hard alloy finished knife grain,

which is low in cost, stable in cutting and beautiful in appearance.

The knife grain contains multiple knife tips that can be used alone and is maintenance-free

and grinding-free,basically realizing zero-cost operation of the equipment.

The planing knife system automatically sets the knife,free of debugging for cutting depth.

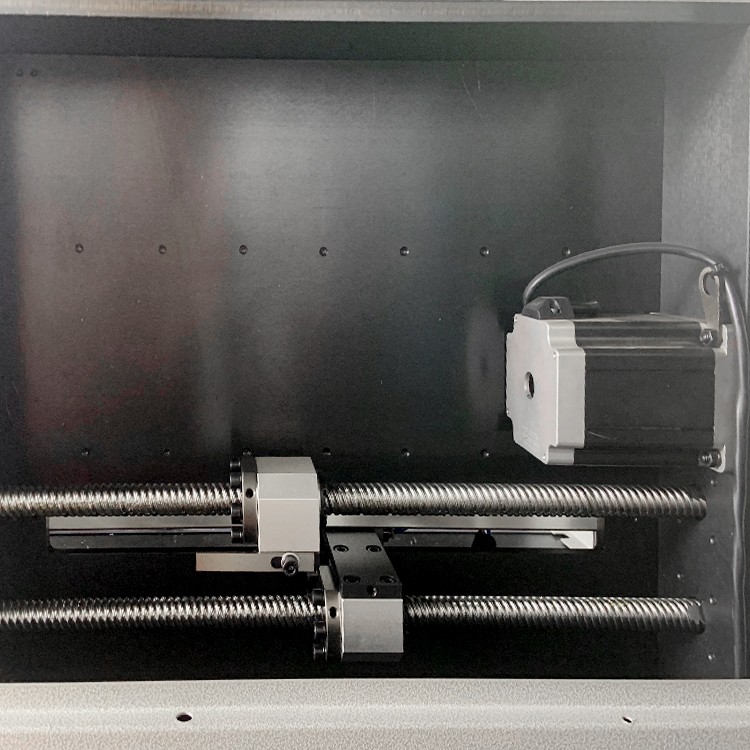

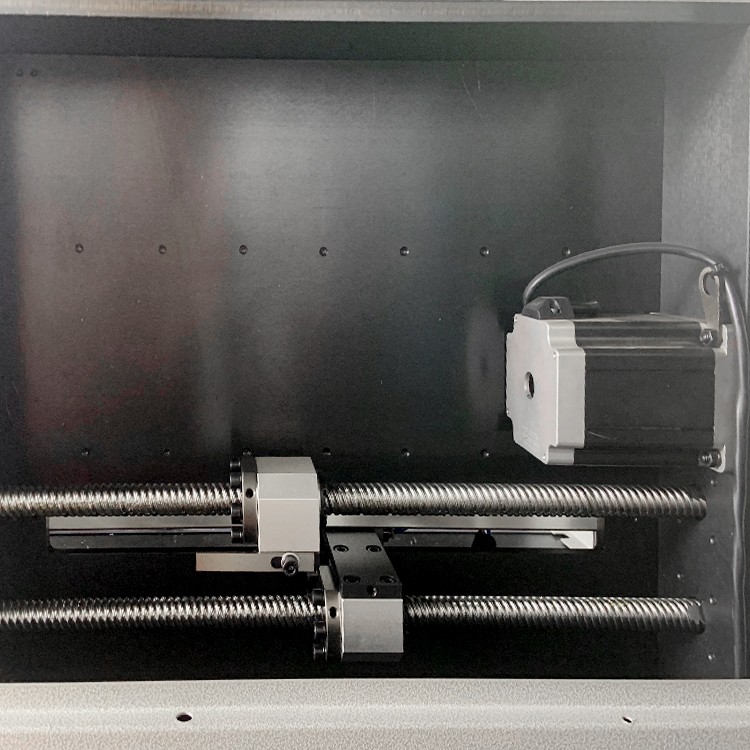

4.

Lead screw plus two-way rail and four-slider positioning transmission,more powerful and

more stable cutting.

5.

High-power servo system control,

High precision,fast speed,large torque,

Improve the efficiency of working.

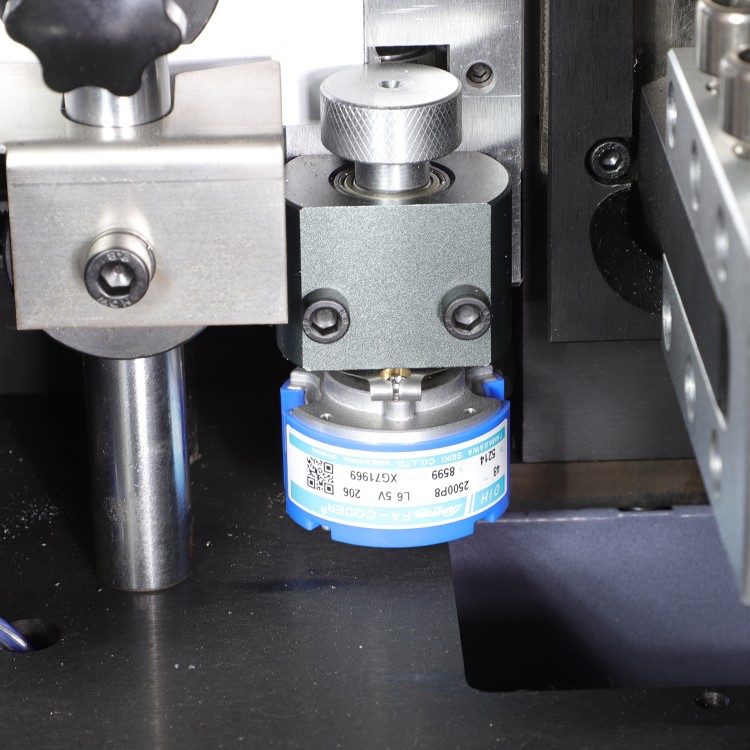

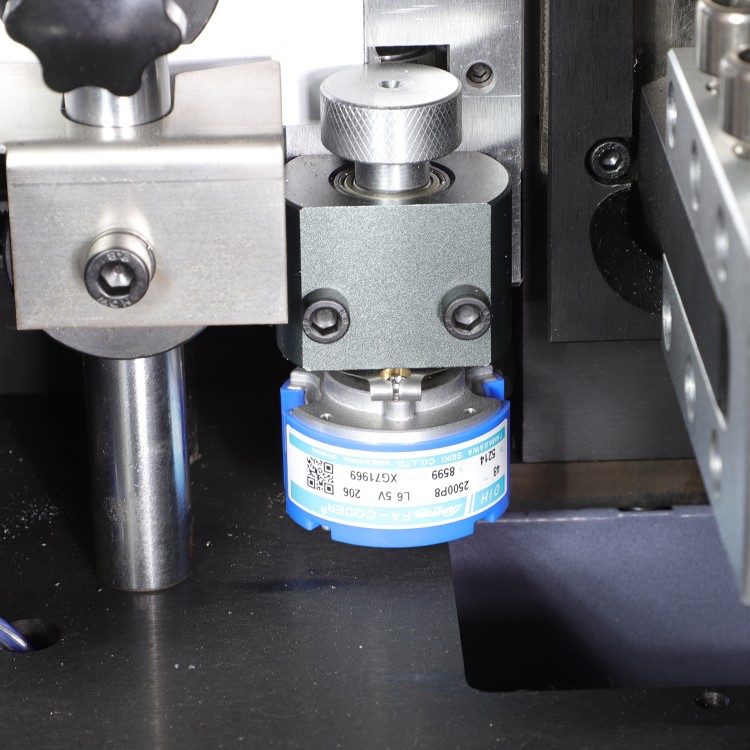

6.

With length closed-loop control system,

length accuracy software control,error ≤ 0.1mm.

7.

Integrated support frame to ensure the stability of equipment feeding.

8.

The software system is easy to learn,easy to operate, professional,

Efficient and thoughtful full service.